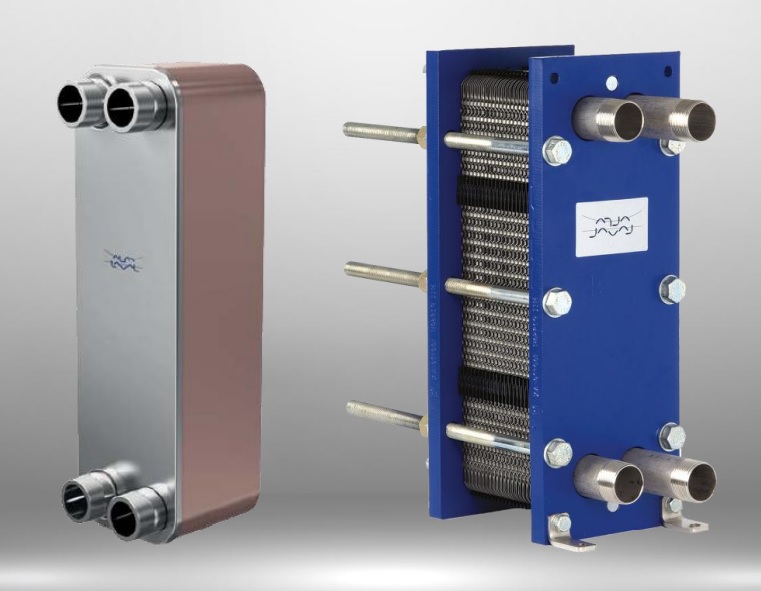

Plate heat exchanger

Plate heat exchangers have been under use from the 1920s to enhance the efficiency of heat exchange and transfer systems. A plateheatexchanger is a kind of heat exchangerwhich uses metal sheets or plates for heat transfer between two fluids. The superiority of these exchangers is that the fluids are distributed across a wider area, since the desired fluids are scattered across the entire plate. This facilitates heat transfer and considerably enhances the fluid’s heat transfer rate. In comparison with other heat transfer systems, plate heat exchangers enjoy the following advantages:

- Employing plateexchangers needs less space. Thus, these systems are very flexible in terms of selection and determination of site of implementing.

- The heat transfer coefficient in plateexchangers is three times as large.

- The extent of heat transfer in these exchangerscan be easily modified. (In the washer-equipped model), this can be possible through increasing or decreasing the number of plates used.

- In plateexchangers, due to the special inner structure of the heat transfer plates, scalesare far less likely to form, compared to other systems. This is because the fluid moves irregularly and there is no dead space or still fluid in the exchanger.

- Compared to other systems, plate exchangers can be easily repaired and equipped. Due to the special design of these systems, they will offer greater efficiency. The higher heat transfer rate will naturally yield greater efficiency. These exchangers are of indirect and immediate fluid heaters, and at the peak time of consumption, they will not have temperature oscillations.

- Plate heat exchangerplates are made of stainless-steel S.S 316. This structure causes the exchanger plates not to be oxidized. Thus, the consumed water will not mix with rust. Further, since only the edges of exchanger plates are exposed to open air, there will be no need for insulation.

- The structure of plate heat exchangers is such that they can be used even under very high pressure and temperature conditions. The plateexchangers of weld type can endure pressure up to 54 bars.

Applications of plate heat changer

Plate heat exchangers can be used in the following industrial and commercial areas:

- Dairies industry (pasteurization process, etc.)

- Food industry

- Petrochemicals industry

- Sugar production industry

- Heating systems in water and pool complexes

- Pharmaceutical industry

- Textile industry

- Heating and cooling systems

Note that the industrial areas of use of these exchangers are not exclusive to the mentioned cases, and any industry or organization that needs heat exchange, use air conditioning systems and HVAC can also benefit from these exchangers.